Automotive security

Security marking for all types of vehicles. Proven to cut theft and raise recovery, adding value for OEMs, dealers & insurers.

Vehicle checks & verifications

200,000+ vehicles checked every year

Comprehensive automotive security marking & registration

Retainagroup provides vehicle manufacturers, import/export centres and dealerships with security marking, registration, and reporting services that reduce theft, support police investigations, and protect business reputations. Vehicles and parts are marked using durable methods such as laser etching, ultra-destructive labels and PET stencils with appropriate etch fluids. Vehicle details are then registered on the International Security Register (ISR) for 24/7 traceability.

Dealers and OEMs benefit from stronger anti-cloning protection, easier verification of replacement parts, and data reporting that helps insurers and authorities track theft trends and recover vehicles faster.

Security marking:

Vehicle windows and/or valuable parts are marked at production plants, import/export centres, or dealerships using a range of methods, including bespoke laser units, stencil & proprietary fluids, electrolysis, and ultra-destruct labels.

Registration & traceability via the ISR

Data from marked vehicles is uploaded onto our standalone servers before being transferred into our International Security Register (ISR). Each code is unique and linked to vehicle identifiers such as VIN, VRM, gearbox, and engine numbers. Checks are available 24/7, providing real-time support to deter theft, cloning and component fraud. Find out more

Analytical reporting

We analyse vehicle loss/theft data (including from PNC/LEDS sources) for manufacturers, insurers, authorities and other relevant parties. We provide reports to meet customer requirements. This includes trend reports, vulnerability assessments and effectiveness evaluations of security systems. Find out more

Trusted by

Trusted by vehicle manufacturers, importers, dealers and insurers

With decades of experience in vehicle security, we are the trusted partner for OEMs, distributors, and dealers. Our systems integrate seamlessly with production processes, are fully scalable, and deliver long-term value by reducing theft and fraud risk.

Technologies that protect

Trusted by manufacturers. Respected by police and law enforcement. Proven by results.

Laser etching

Lasers are a proven technology for marking unique codes in glass. Delivering fast, precise and durable results. Ideal for high-volume production and large fleets.

Stencil & fluid

Cost-effective, flexible, and easy to apply with minimal investment, making them a practical choice for dealerships, regional distributors, and small manufacturers.

Electrolysis & metal etching

Permanent, tamper-resistant marks for bare metal, providing discreet identification for Catalytic converters and other components.

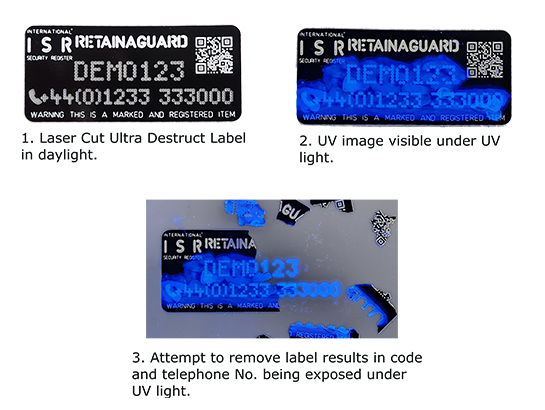

UV & ultra-destruct labels

Suitable for plastics and painted parts, providing tamper evidence and discreet identification for component manufacturers, aftermarket suppliers and dealerships.

Proven protection

Law enforcement data indicates that both vehicle and asset marking substantially decrease the chances of theft for cars and valuable belongings alike.

Vehicle window marking

A simple, safe, and effective system for marking a vehicle's glass at a production plant, import/export centre or dealership.

Permanent marking on vehicle glass with unique ISR codes deters theft, prevents cloning, and provides lifetime traceability for faster recovery. Window etching is one of the most widely used automotive marking methods. By permanently marking vehicle glass with a unique ISR-linked code, manufacturers, import centres and dealerships can deter theft, prevent cloning and provide lifetime traceability. Marked windows make stolen vehicles far harder to sell and far easier for police to recover

Vehicle marking explainer video

Our glass marking system is simple, safe and effective. Operators can be trained in minutes, and no capital equipment or protective clothing is required. The process marks only the glass, leaving paintwork and other vehicle parts untouched. Water acts as the neutralising agent, and an MSDS sheet is available on request for full safety information.

Metal marking with stencil and fluid

Permanent identification for bare metal surfaces.

Our stencil and fluid system offers a clear, durable way to mark aluminium, steel, and other metals. Using laser-cut ultra-destruct labels with a custom fluid, parts can be identified visibly and permanently. This method is widely employed to protect catalytic converters from theft, making it more difficult for criminals to resell stolen parts and easier for police and insurers to trace ownership.

Catalytic converter protection

Catalytic converters are a common target for thieves. Our CatGuard system places a unique, permanent mark on converters, registered with the International Security Register (ISR). This makes stolen converters traceable and assists police in identifying offenders.

UV self-etch labels

Permanent marking for painted metal surfaces.

Our ultra-destruct UV labels offer permanent identification without fluids. Once applied to painted metal, the unique code and ISR contact details are engraved into the surface within seven days. If removal is attempted, the label breaks apart and the code remains visible under UV light, ensuring long-term traceability and discouraging theft.

Ultra-destruct labels with uv fluid

Durable marking for plastics and painted metals.

This system utilises laser-cut ultra-destruct labels combined with our proprietary UV fluid. Once applied, the label bonds securely to the surface, and any attempt to remove it causes it to break apart. Even if the label is entirely peeled off, the UV fluid leaves a permanent code and ISR contact details on the item, visible under UV light. Suitable for plastics as well as painted metals, it offers durable identification and effective theft deterrence.

Ready to protect your vehicles?

Join the manufacturers who trust Retainagroup for their security protection requirements.

International Security Register (ISR) 24/7: +44 (0)1233 333000

Sales & General: +44 (0)1233 504167

Email: info@retainagroup.com

Unit 5, St John’s Court,

Foster Road, Ashford Business Park,

Ashford, Kent,

TN24 0SJ,

United Kingdom

Check online the status of a marked and registered motor vehicle or any other item protected by our system: